Description

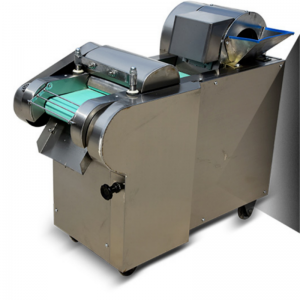

With the development of the times and the advancement of science and technology, manpower is becoming more and more weak in front of machinery, especially when Industry 4.0 is around the corner, the machinery automation is the general trend. The chili stem cutting machine was born in this situation. What are the advantages of the chili stem cutting machine compared with the traditional manual cutting machine? 1. The traditional manual chili scissors are time-consuming, labor-intensive and extremely inefficient, and also, because chili is pungent, if you are engaged in manual scissors work, it will cause great harm to the human body, such as limb deformation, skin diseases, eye irritation and other serious injuries . At present, young people are reluctant to engage in this job no matter how much salary it is. It is difficult to employ, with high turnover rate and low efficiency, which is a very big problem in the chili processing industry. And all the above problems can be easily solved by the chili stem cutting machine. The fully automatic machine produced by our company is mainly used for removing dry chili stems. The removing rate of the equipment to chili stems can be as high as 97%. 600KG per hour, and can be adapted to different varieties and chili shapes according to customization, and the performance of the whole machine has reached the international leading level. The main part of the machine is supplemented by auxiliary equipment such as impurity removal and transportation, which can reduce labor cost and greatly improve work efficiency.

The chili is fed from the feed port through an arc guide and then falls into the drum, and the drum rotates quickly to complete the removal work. The drum of the chili stem cutting machine has a certain slope, and the chili rolls forward while rolling, and finally falls out of the drum and is discharged smoothly. A chili shears machine with good performance can clean the peppers on the basis of ensuring a removal rate of more than 97%. The chili machine completely uses machinery to replace manual labor, which not only reduces human injury, but also saves time. Chili stem cutting machine equipment has high cutting capacity, low pepper loss, high efficacy, adapts to different varieties and pepper shapes (customized), and the efficacy of a single machine is more than 5 times that of ordinary products in the market. The use of pepper removal machine, with the shortage of labor and the increase of labor costs, the realization of the mechanization of pepper removal is the key to solving the problem. It is time-consuming and labor-intensive to remove pepper stems by hand and is extremely inefficient. The chili machine can process dried chili, and can also process fresh chili. The chilli removing machine has reasonable structure and simple operation, just plug in the power and start the machine, only one person needs to pour the chilli into the hopper.

Selection of chili stem cutting machine:

1. Confirm the chili varieties to be processed. At present, there are three representative appearance chilies on the market: Banjiao represented by Beijing red, small chili represented by Indian s17, and linear chili represented by Erjingtiao. Different varieties require different types of chili machines.

2. Confirm the model according to the processing volume. Now our machines are available in three different processing capacities ranging from 250 kg to 400 kg per hour.

3. After confirming the above two items, it is necessary to inspect the actual processing performance of the machine and conduct on-site inspections. Its performance indicators mainly include shearing rate, processing capacity, and notch sharpness. The larger the first two, the better, and the smaller the latter, the better.

Fourth, the brand is also an important one. Brand is a comprehensive reflection of quality, reliability, after-sales service and reputation. Every aspect has been tested by the market, and the quality will be quite guaranteed. The counterfeit brand that has just set foot has no actual production experience, and the product quality, after-sales service, credit, etc.

5. About additional functions. Some manufacturers cannot promote the functions of products in the market, and make some tricks. The core function of the machine is stem cutting, and the other supporting functions are all for stem cutting, so do not put the cart before the horse.